Conformal coating: Nano-coating, vapor deposition; to meet the actual needs of customers' products, develop one-to-one solutions, tailor-made processes for product manufacturing, application environment and other specific needs, to ensure product reliability and service life.

Through the actual demand of the customer's products, the company has developed a professional three-proof material selection, tailored to the specific needs of the customer's actual manufacturing and application environment, and customized and perfected the three-proof process to provide protection for the product's three defenses.

The perfect process quality control system has solved the common problems in the manufacturing industry caused by the three-proof design and manufacturing process for the high-end field, and has been recognized by N+ customers.

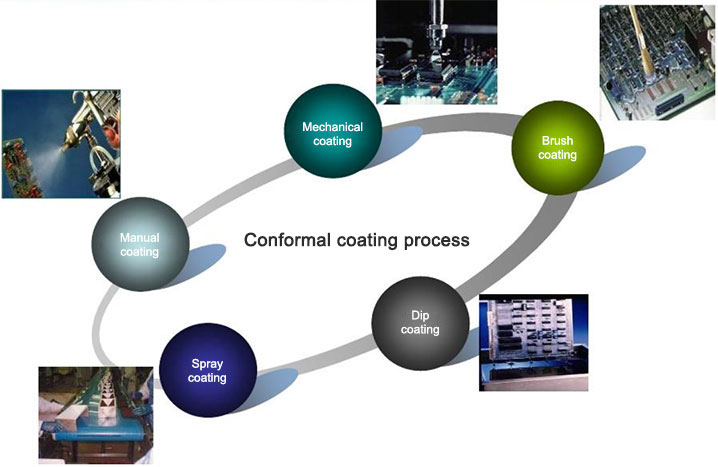

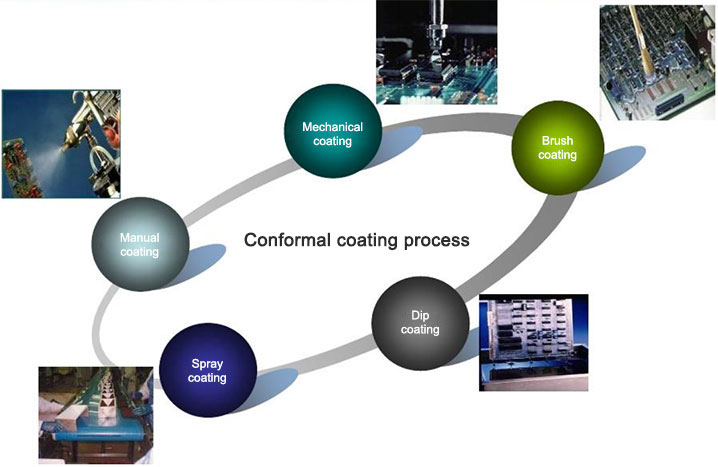

Conformal coating applied to PCBA (printed board assembly) with an insulating protective layer conforming to the shape of the object being coated:

a. The purpose of the conformal protective coating is to protect the PCBA from the impact of harsh environments on circuits and components during operation and storage, and to increase the shock and vibration resistance of the device to achieve moisture, mildew and salt spray corrosion resistance.

b. Prevent "condensation" due to sudden changes in high temperature, resulting in increased leakage between solder joints, short circuits, and even breakdown.

c. Prevent “crawling” between high voltage circuit leads.